Products By

-

Category

CategoryPower Transmission

- Micro-V Belts Micro-V Belts

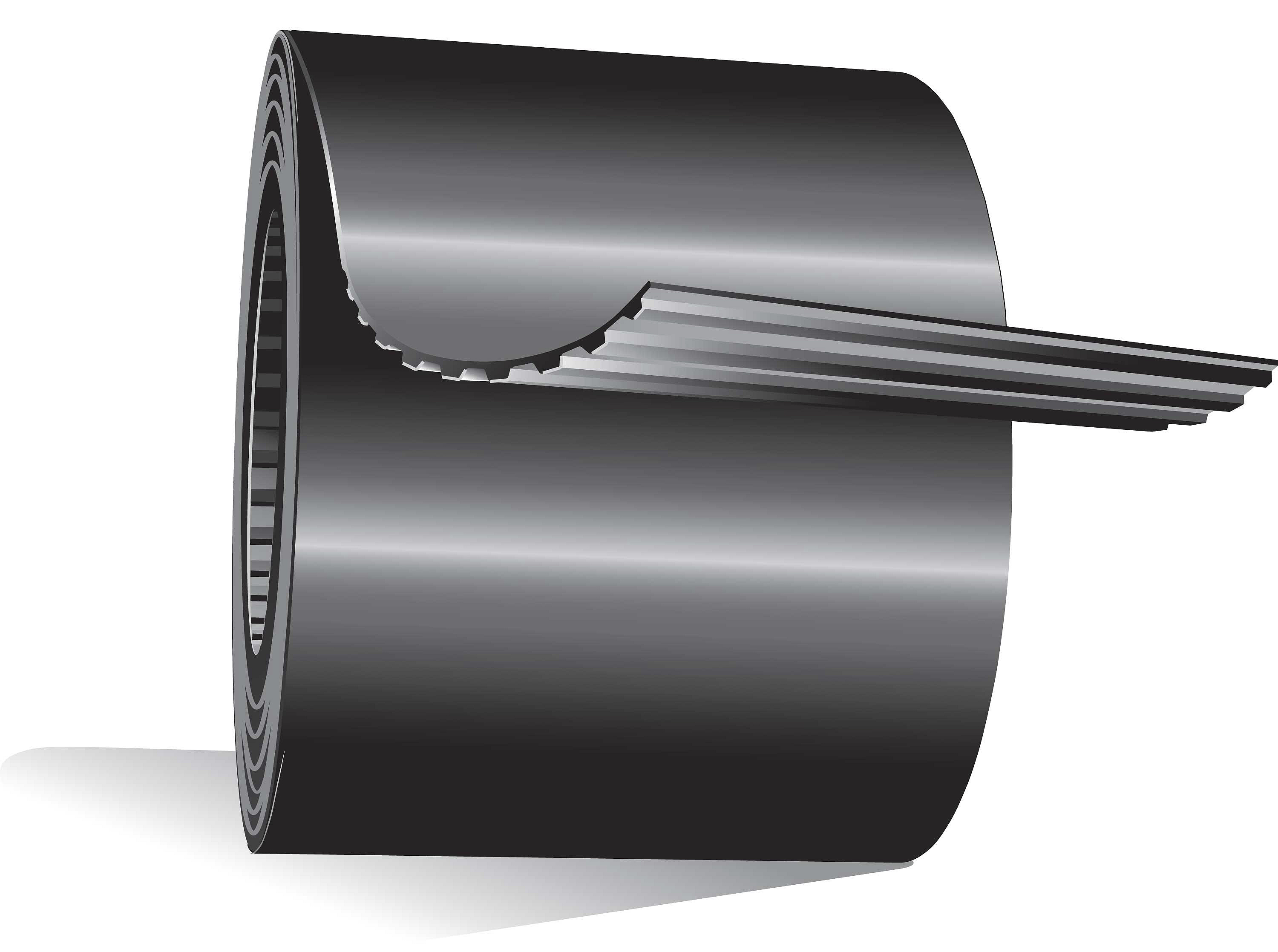

- V-Belts V-Belts

- Special Belts Special Belts

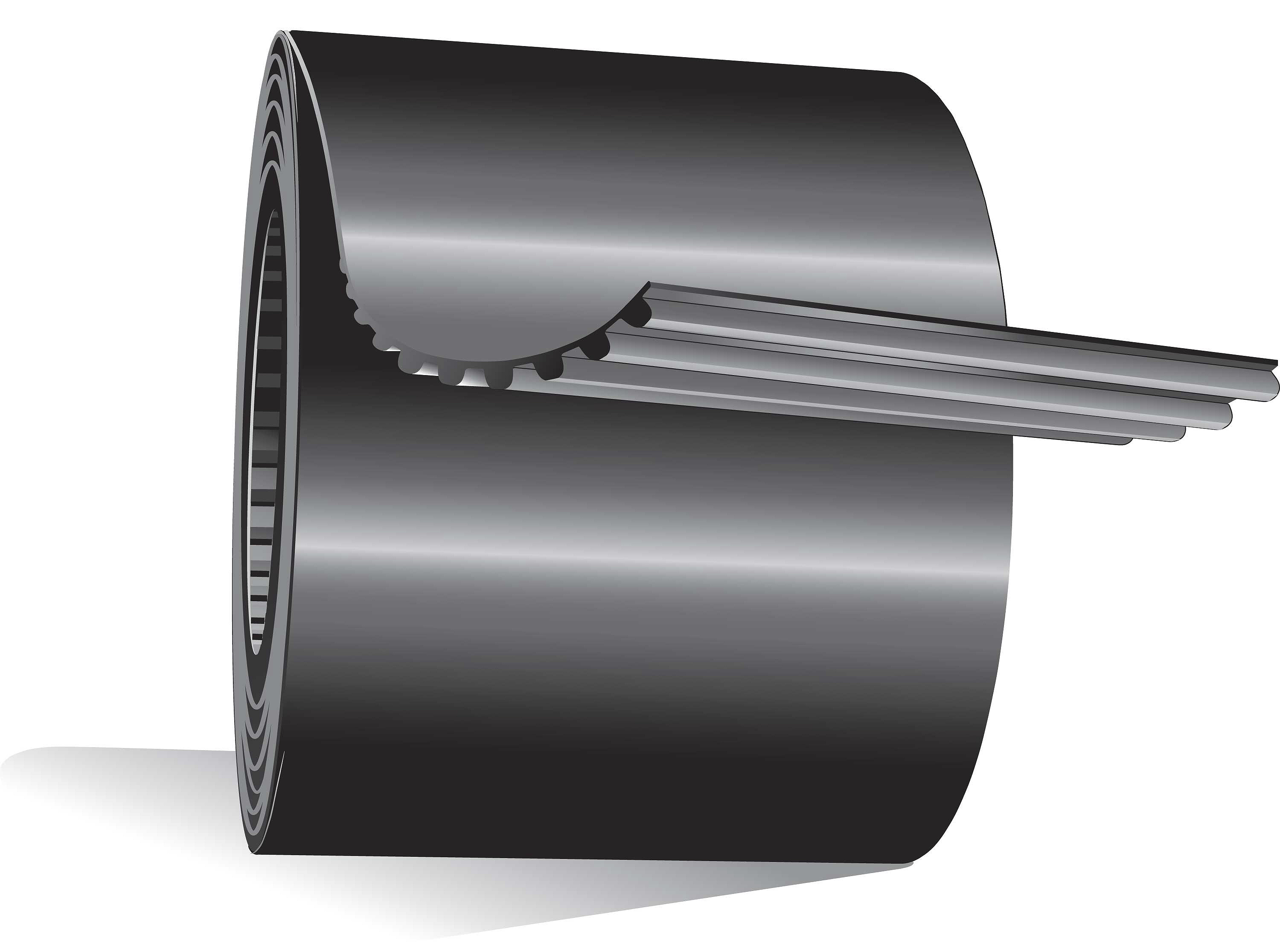

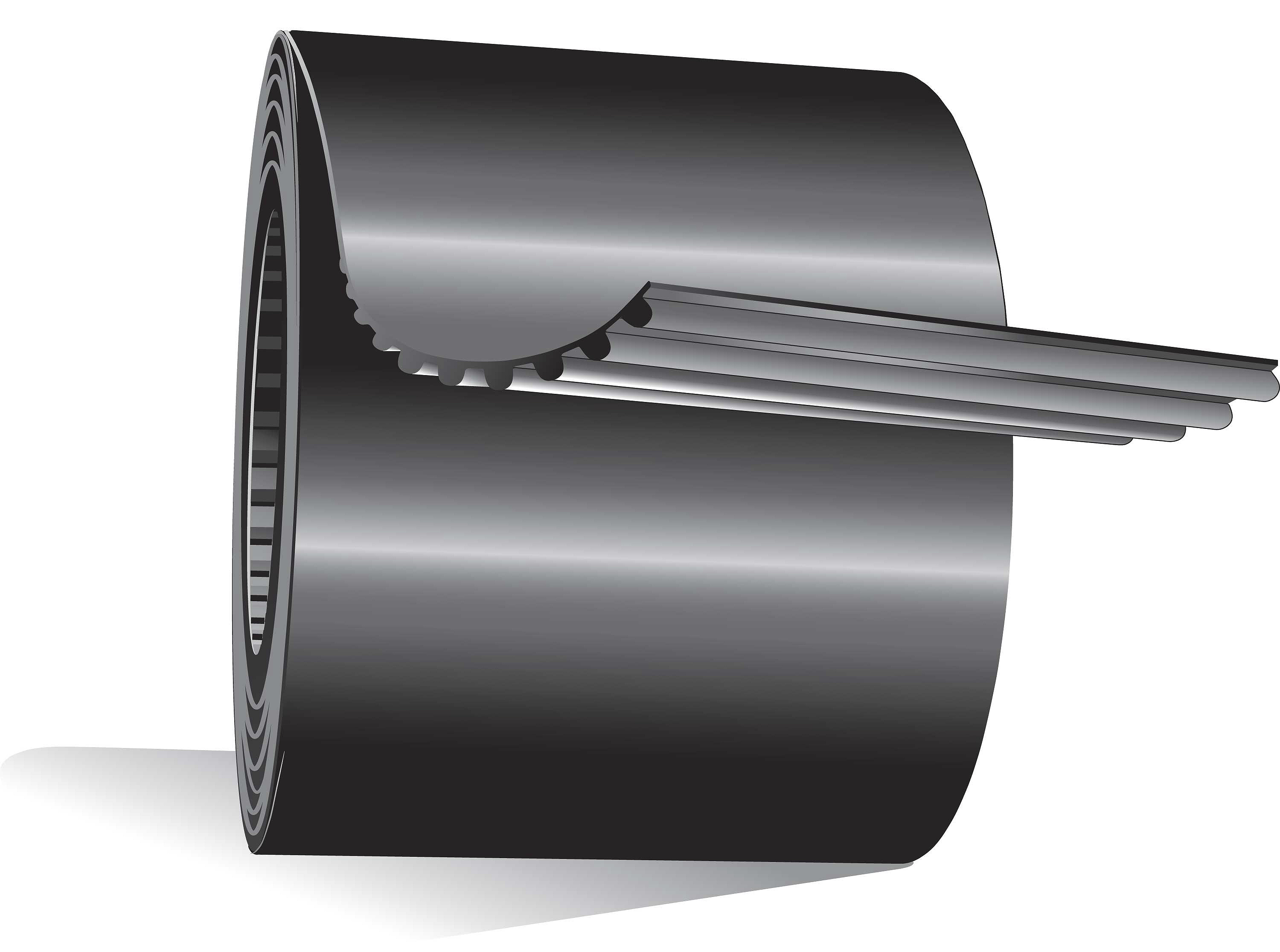

- Synchronous Belts Synchronous Belts

- Automotive Timing Belts Automotive Timing Belts

- Gates TPU Polyurethane Belting Gates TPU Polyurethane Belting

- Power Transmission Components Power Transmission Components

- Water Pumps Water Pumps

- Power Transmission Kits Power Transmission Kits

- Power Transmission Tools and Merchandisers Power Transmission Tools and Merchandisers

Fluid Power- Hydraulic Hose and Couplings Hydraulic Hose and Couplings

-

Hydraulic Hose and Couplings

- Air Brake / Compressed Air

- Ball Valves

- Brass Adapters

- Hydraulic Accessories

- Hydraulic Adapters and Valves

- Hydraulic Equipment and Crimpers

- Hydraulic Hose Assemblies

- Live Swivels

- PTFE Hydraulic Hose and Couplings

- Quick Disconnect Couplers

- Spiral Wire Hose and Couplings

- Textile Braid Hose and Couplings

- Thermoplastic Hose and Couplings

- Wire Braid Hose and Couplings

- Hydraulic Tubing and Tube Fittings Hydraulic Tubing and Tube Fittings

- Industrial Hose Industrial Hose

- High Pressure Oilfield Hose High Pressure Oilfield Hose

- Fluid Power Tools and Merchandisers Fluid Power Tools and Merchandisers

- Engine Hose Engine Hose

-

Engine Hose

- Air Conditioning Hose and Couplings

- Coolant Hose

- Coolant Tanks

- Fuel Line Hose

- Heater Control Valves

- Heater Hose

- Power Steering

- Hose Clamps and Couplings

- Cooling Fan Modules

- Turbocharger Oil Line

- SCR

- Vacuum Tubing

- Transmission Oil Cooler Hose

- Air Brake / Compressed Air

- Other Engine Hose

- Air Intake and Defroster Hose

- Air Vent Hose

- Emission Control Hose

- Fuel Fill Hose

- Turbocharger Hose

Urban Mobility & PowersportsOther Products- Automotive Accessories Automotive Accessories

- Caps and Thermostats Caps and Thermostats

- Engine Hose (Air Intake/Emissions) Engine Hose (Air Intake/Emissions)

- Service Station and Shop Support Hose Service Station and Shop Support Hose

- Windshield Washer, Wiper and Vacuum Components Windshield Washer, Wiper and Vacuum Components

- Markets

- Innovations & Solutions

backInnovations & Solutions

- Innovations

- Data Master™ Data Center Cooling Hose Family

- eCrimp™ Hydraulic Crimp Database

- GC20™ IoT Hydraulic Hose Crimper

- MegaSys™ MXG™ Premium Hydraulic Hoses

- MegaSys™ MXT™ Premium Hydraulic Hoses

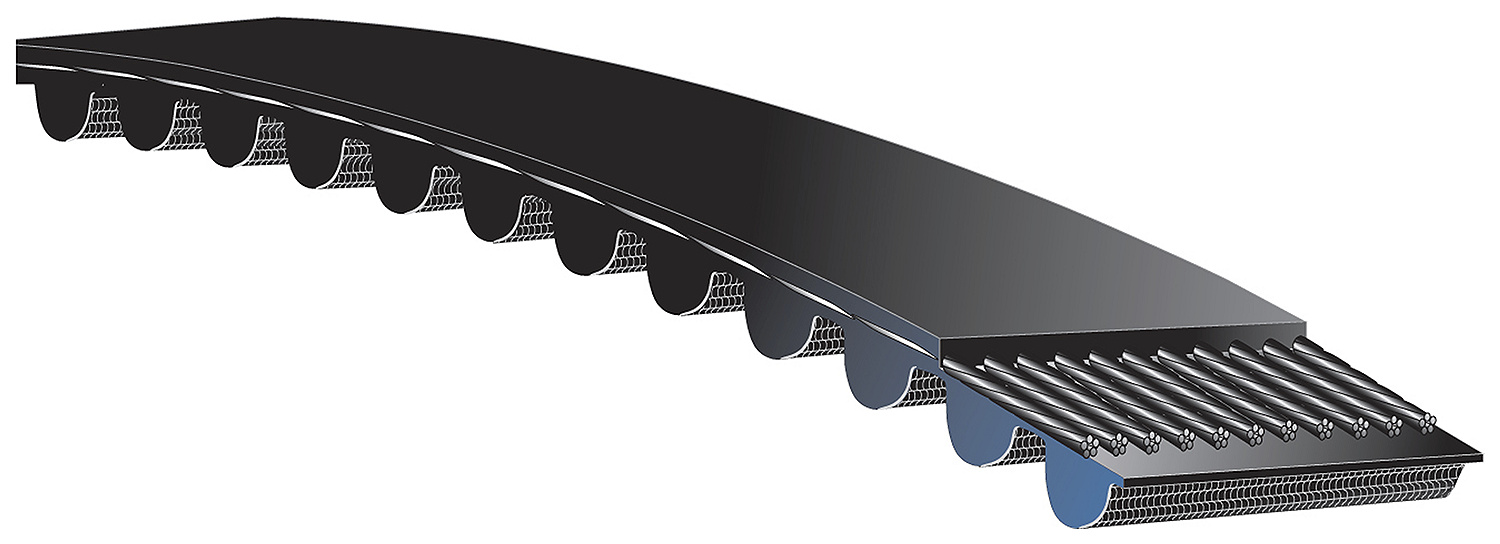

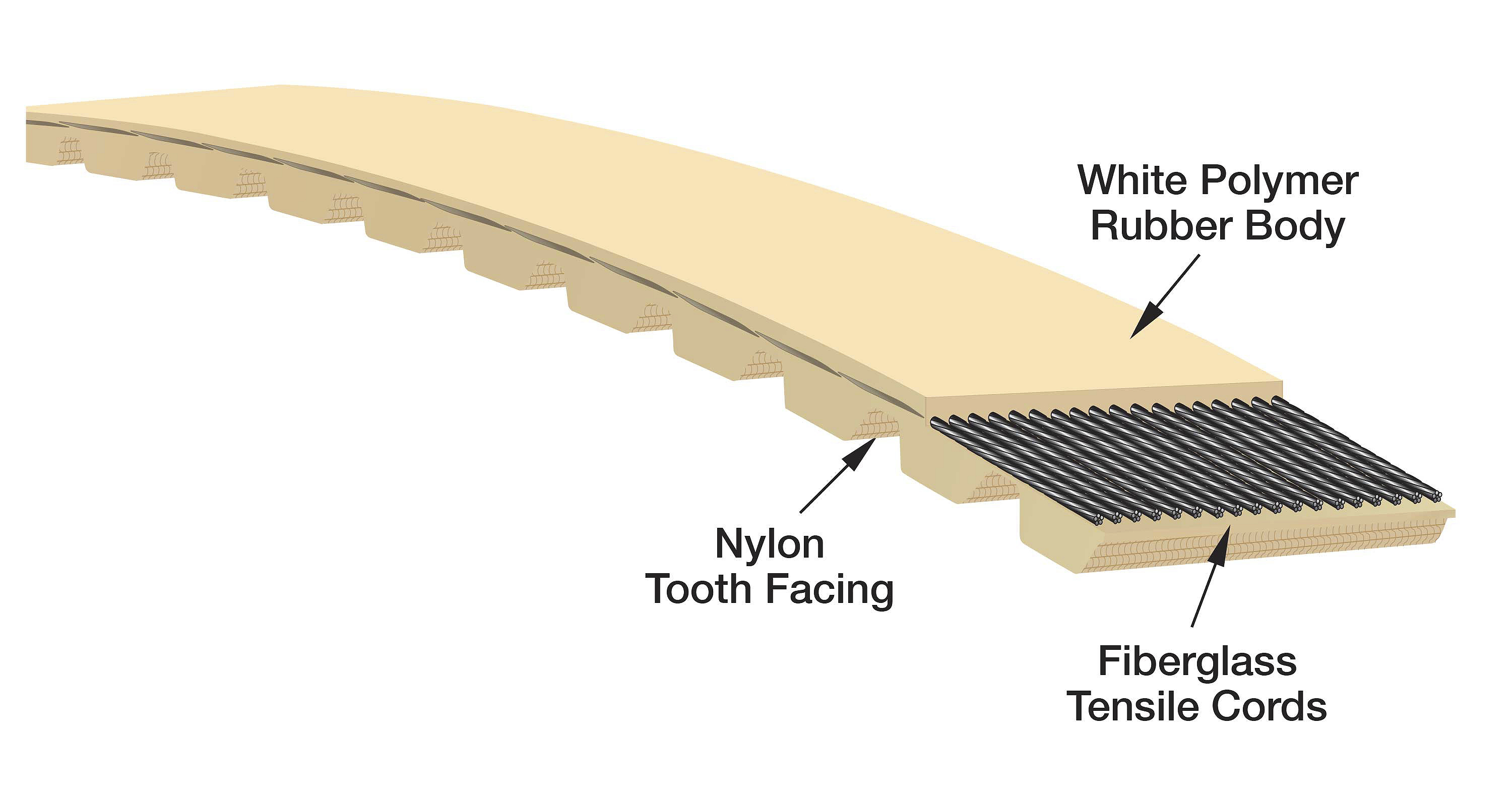

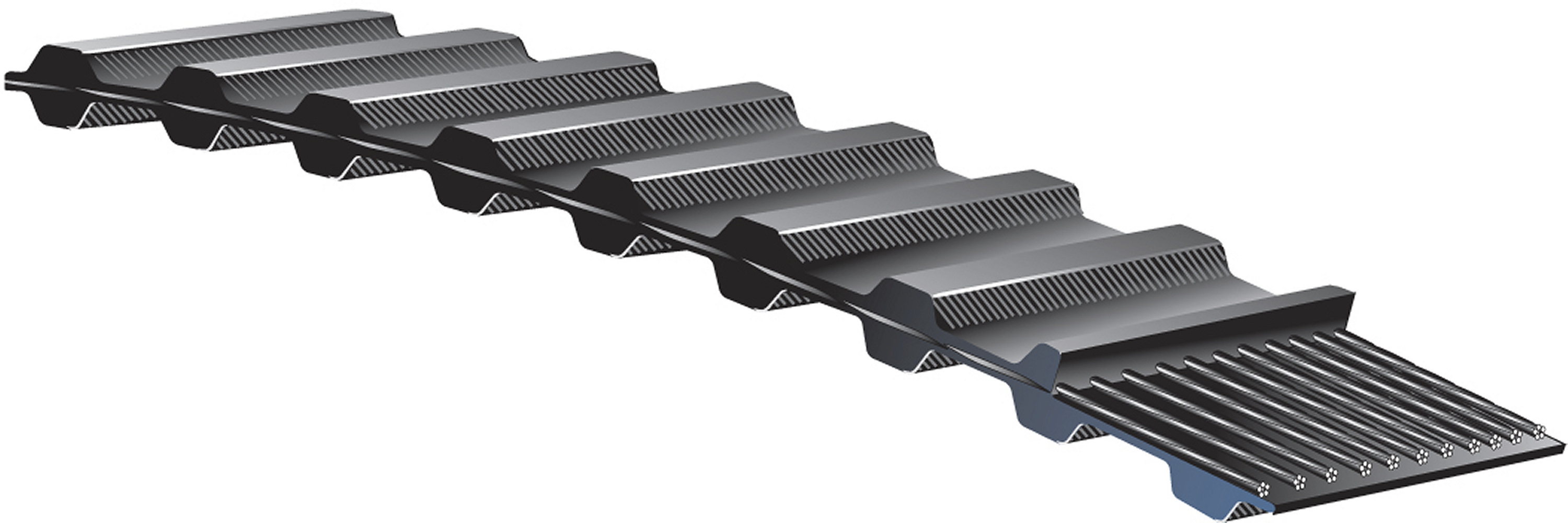

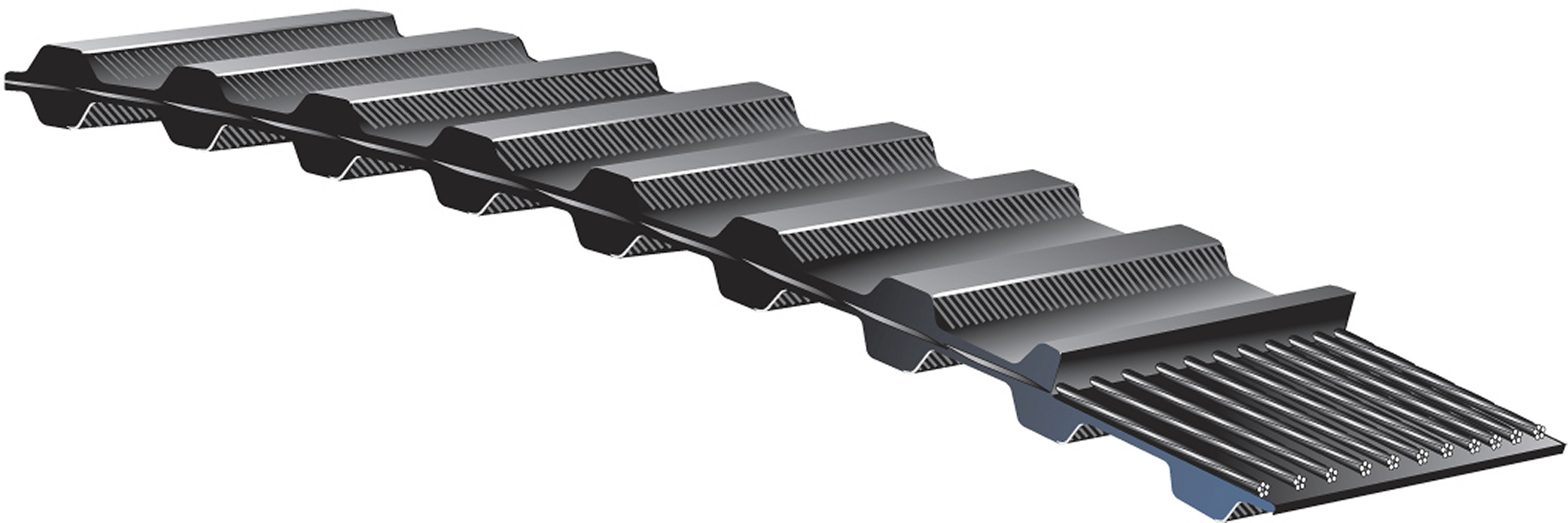

- PowerGrip™ GT™ 4 Synchronous Belts

- ProFlex™ Hydraulic Hose

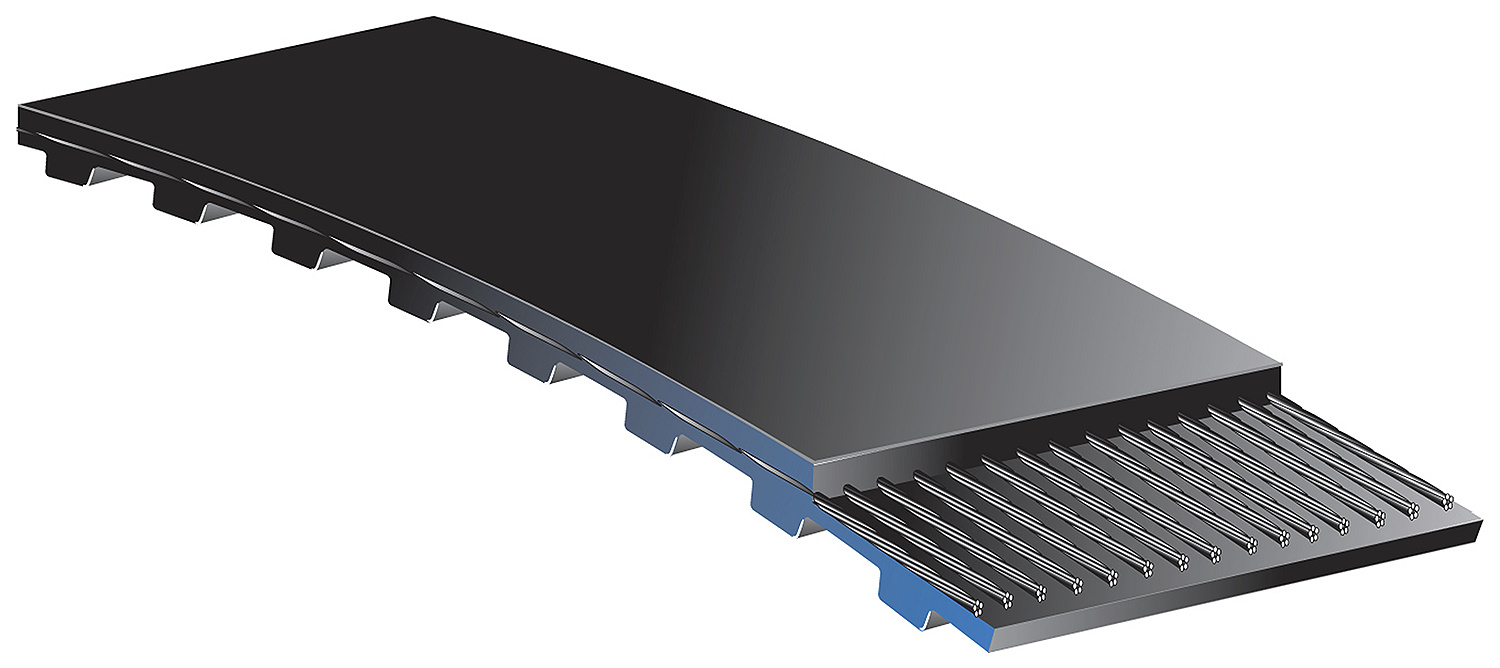

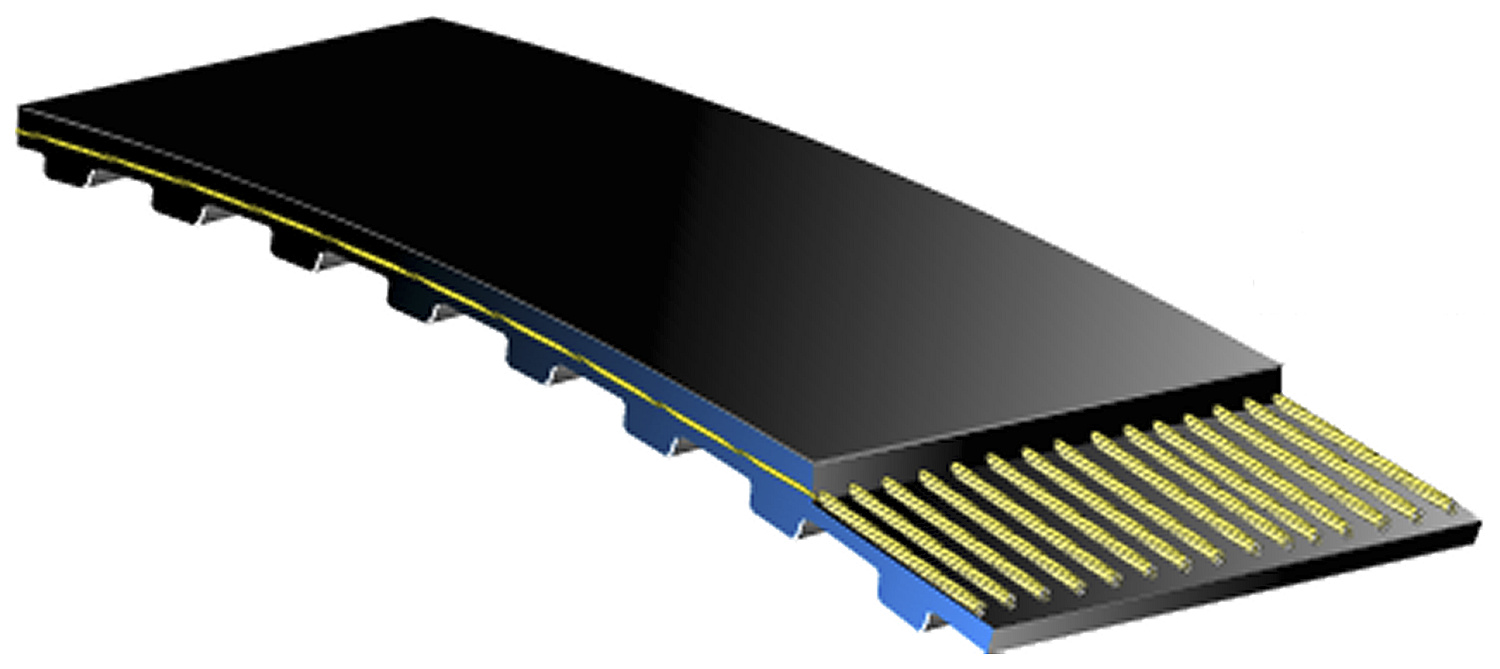

- Quad-Power™ 4 Bandless V-belts

- ThermalPro™ Electric Water Pumps

- Xtreme V-Force™ Mega Banded V-Belt

- Industrial & Off-Highway Solutions

- Chain to Belt

- Data Center Cooling Systems

- Design Power™

- Industrial Bandless V-Belts

- Industrial Cleaning Solutions

- Industrial Hose Range

- Industrial Synchronous Belts

- MegaCrimp™ & GlobalSpiral™ Couplings

- MegaSys™ Premium Hydraulic Hoses

- Self-Assembly Hydraulic Crimping Machines

- Thermoplastic Polyurethane Belts

- Automotive & On-Highway Solutions

- Urban Mobility & Powersports Solutions

- Innovations

- Knowledge Center

- About Us